Monday, February 23, 2026

3D Printing and the Revolution few people know about.

In 1950, the United States controlled a monopoly on manufacturing. 50 years later, manufacturing had relocated to developing countries like Japan, Korea, Taiwan, China, India, and Mexico. Over the next 50 years, a noticeable amount of manufacturing will relocate again, this time into the kitchen, home office, or garage.

They call it "additive manufacturing." Unlike traditional manufacturing, which carves material away from the bar stock (block of material you start from to shape a part), additive manufacturing is a reverse process: starting with nothing, then adding molecule to molecule, like building with Legos, until a part is formed.

What are Legos?

In 2000, I wrote an essay on molecular manufacturing and nanotechnology. The futurists back then were predicting a revolution in manufacturing equivalent to the revolution in information, which started 500 years ago when only the elite had access to information—that is, until the printing press was invented—and now, 500 years later, anyone in the world can access and publish from their home.

The same sort of revolution is happening in manufacturing, but it will take less than 50 years. In the near future, instead of purchasing something that was made in China, you will now download or create your own design specs and then manufacture what you want in your kitchen, office, or garage. You will grow your goods like a plant.

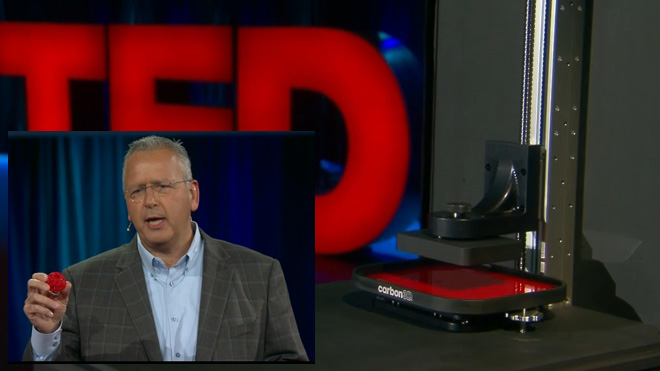

The new 3D printer demonstrated at TED has four significant improvements. It’s 25–100x faster, the parts are both smoother and stronger at the molecular level, and now it can be manufactured from a wider variety of materials. This is not the same 3D printer—just improved; this printing process is a completely new invention.

This technology is a step closer to greater independence and customization for the individual, the family, and the [New State].

Source: ted.com - What if 3D printing was 100x faster?

END

They call it "additive manufacturing." Unlike traditional manufacturing, which carves material away from the bar stock (block of material you start from to shape a part), additive manufacturing is a reverse process: starting with nothing, then adding molecule to molecule, like building with Legos, until a part is formed.

What are Legos?

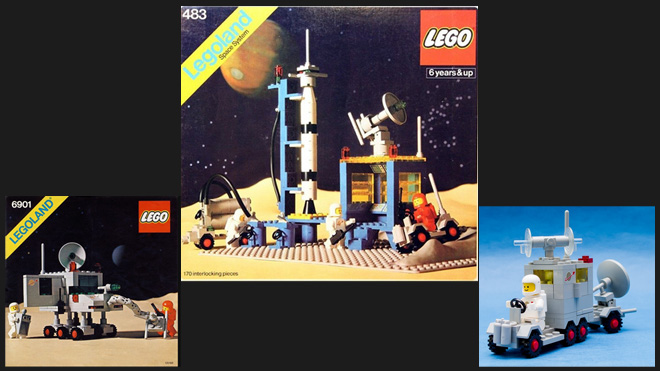

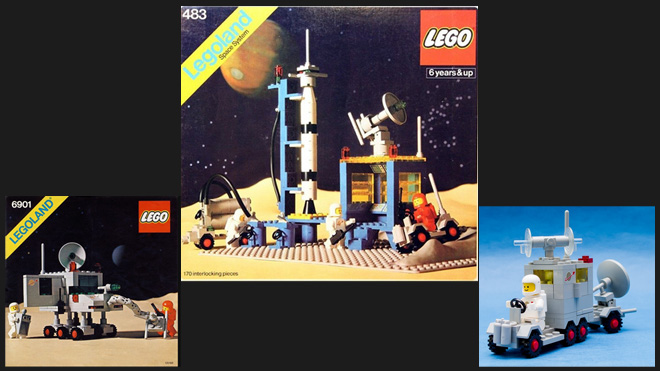

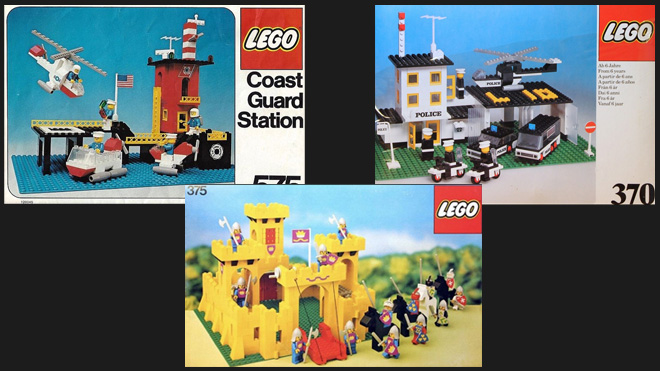

I had the Galaxy Explorer and a bunch of other Lego pieces.

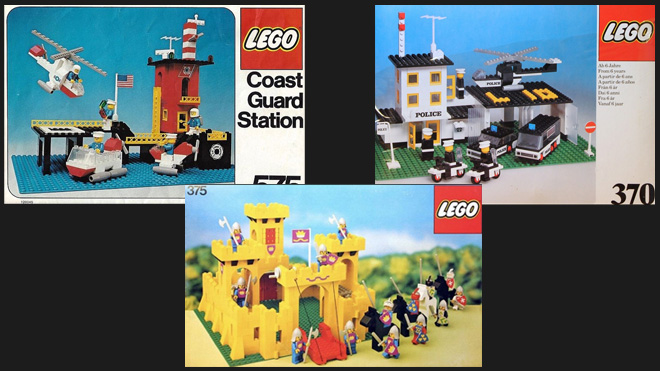

All the Legos in these photos are from around 1978–1981. These were real Legos, unlike most of the Legos sold today. Back then, Lego pieces were small and more generic. That allowed us to be imaginative engineers and create just about anything, not just what was pictured in the box. Many (but not all) of today’s Lego pieces are more fully formed and specific to the set, limiting the builder to just following instructions to build what’s pictured on the box. When you get to the end of the instructions, you’re finished.

All the Legos in these photos are from around 1978–1981. These were real Legos, unlike most of the Legos sold today. Back then, Lego pieces were small and more generic. That allowed us to be imaginative engineers and create just about anything, not just what was pictured in the box. Many (but not all) of today’s Lego pieces are more fully formed and specific to the set, limiting the builder to just following instructions to build what’s pictured on the box. When you get to the end of the instructions, you’re finished.

My friend had the Space System and some moon vehicles.

Notice the thousands of brick snap fasteners that bind each piece together. It reminds me of the pixilated 3D world of computer-aided design and video games that would follow in the next few decades. Could it be that the world humans evolve our lives into, including our bodies, will be the virtual world before we explore deep space?

Notice the thousands of brick snap fasteners that bind each piece together. It reminds me of the pixilated 3D world of computer-aided design and video games that would follow in the next few decades. Could it be that the world humans evolve our lives into, including our bodies, will be the virtual world before we explore deep space?

My friend also had these sets.

By the way, delight in a metaphor:

*Legos are like an octopus: they have suckers and can change shape.

By the way, delight in a metaphor:

*Legos are like an octopus: they have suckers and can change shape.

In 2000, I wrote an essay on molecular manufacturing and nanotechnology. The futurists back then were predicting a revolution in manufacturing equivalent to the revolution in information, which started 500 years ago when only the elite had access to information—that is, until the printing press was invented—and now, 500 years later, anyone in the world can access and publish from their home.

The same sort of revolution is happening in manufacturing, but it will take less than 50 years. In the near future, instead of purchasing something that was made in China, you will now download or create your own design specs and then manufacture what you want in your kitchen, office, or garage. You will grow your goods like a plant.

The new 3D printer demonstrated at TED has four significant improvements. It’s 25–100x faster, the parts are both smoother and stronger at the molecular level, and now it can be manufactured from a wider variety of materials. This is not the same 3D printer—just improved; this printing process is a completely new invention.

This technology is a step closer to greater independence and customization for the individual, the family, and the [New State].

Source: ted.com - What if 3D printing was 100x faster?

END